Spirit of innovation and cutting edge machinery

To ensure the speed and flexibility of our mechanical constructions, we made sure to equip ourselves with the best technology, machinery and equipment. A fleet of articulated machines that allows us to internally carry out all the operations necessary to produce the finished product, checking its development step by step. However, for a company built on the most modern and enterprising traditional craftsmanship, like our mechanical engineering workshop, the human component – with its desire to experiment and innovate – is the indispensable element for attaining success.

The variety of machines allows to run internally most of the operations that lead to the finished product. The work ranges from component oxyfuel, painting, assembly and testing possible. This allows the constant, direct control of the quality and production optimization.

- Workstation CAD – CAM 3D

- 10 synergic welding Fronius 500 A

- Linear welding system L=7000

- 4 welding positioners – maximum load 4500 kg

- Iveco Truck 180.28 with crane – maximum load 5 ton

- Corradini crane – maximum load 24 ton

SORALUCE FS 12000

Milling machine with travellin g column Soraluce FS 12000.

Travel 12,000 X 3,200 X 15,00 with rotating table 2,000×2,000m, capacity 20 tons

SORALUCE TR 35

Milling machine with fixed table Soraluce TR 35.

Travel 3,500 X 1,600 x 1,200

TORNIO HYUNDAY KIA SL 400

Hyundai K st1 400 LMC CNC lathe with driven tools.

Bit height 400 X 2,100 travel

PLASMA

Plasma + oxyfuel cutting system with drilling equipment.

Travel 14,000 x 3,500

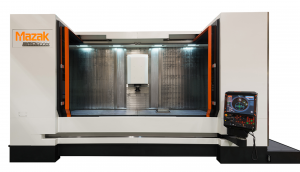

Centro di lavoro verticale VTC-800-30HD 2X3

Travel 3000 x 800 x 720